Armistead offers its customers several innovative services that are vital in bringing projects in on time and within budget. They also contribute to the precise, high-quality service we provide our customers.

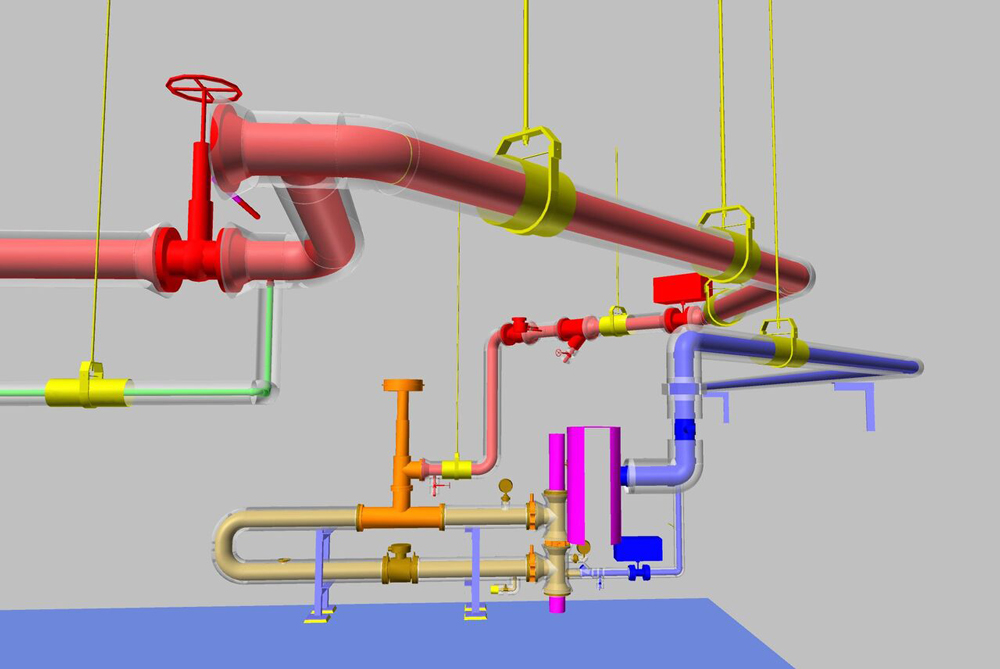

3D COORDINATION & VDC

Armistead can conceptualize your mechanical system and prepare it for manufacturing and testing using our virtual design in construction technologies. Utilizing various design levels, we can isolate and define the scope of work and show mechanical systems, assemblies and sequences in relative scale with the entire facility or project. This innovative software system facilitates better cost and project management and provides Armistead the opportunity for earlier decision making, evaluation and analysis before construction even begins.

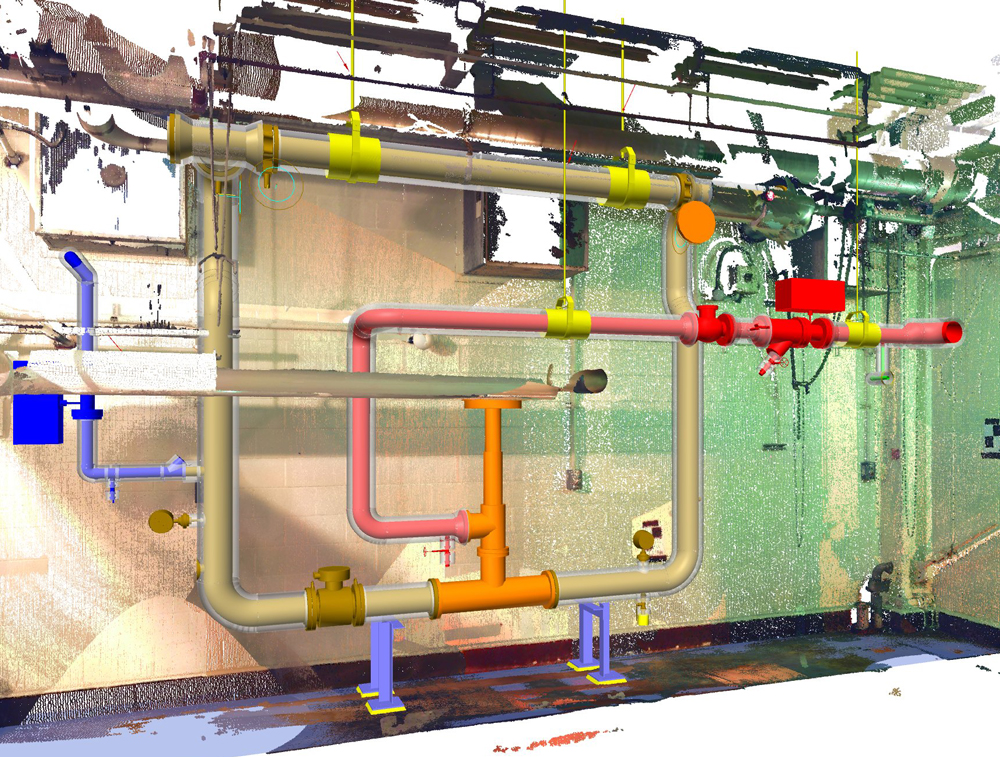

LASER SCANNING & ROBOTIC LAYOUT

In conjunction with Autodesk Fabrication, Sysque, Revit and Navisworks software, our Trimble Total Station and 3D laser scanner are used for data collection in the field and to provide layout information. This allows us to complete work faster and with more accurate fabrication and trade coordination.

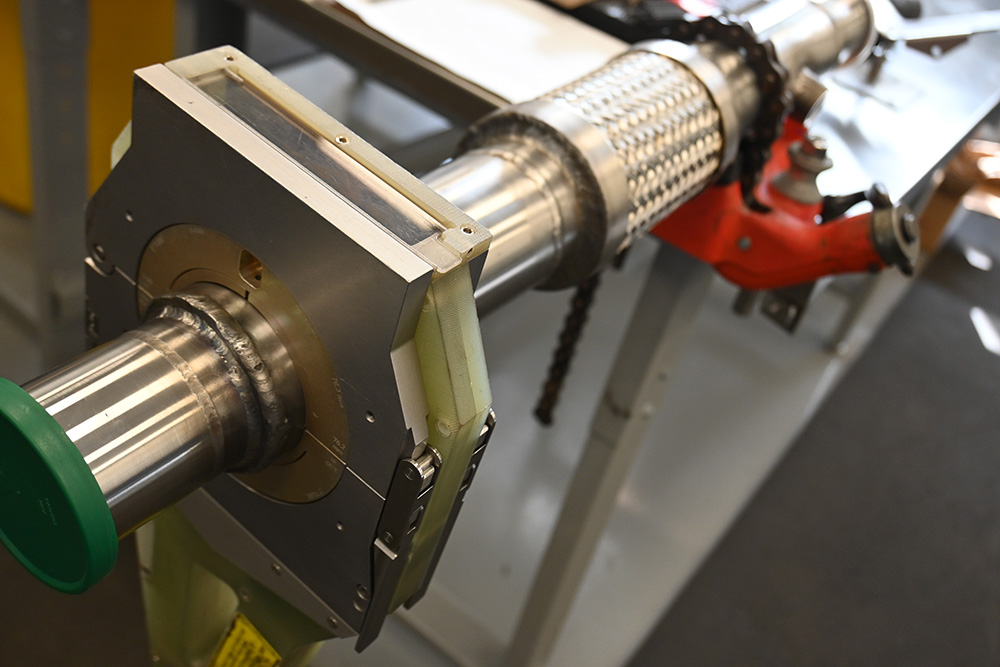

COMPUTERIZED ORBITAL WELDING

A high quality weld that meets cGMP standards (Current Good Manufacturing Practices) for industries like food processing, pharmaceuticals and semiconductor can only be achieved from the process of orbital welding. Armistead utilizes Arc Machines, state-of-the-art computerized orbital welding equipment to provide cGMP-approved sanitary piping systems to a variety of markets. All of Armistead Mechanical’s welding services meet the most demanding ASME codes and ANSI standards. Clean room facilities in both our New Jersey and New York locations facilitate these types of installations.

PREFABRICATION

Piping prefabrication provides Armistead with a competitive edge and is a key component of our project management philosophy. It plays a major role in scheduling, which is so critical in many of our pharmaceutical, hospital and high-tech projects which are normally fast-tracked. Our teams employ prefabrication whenever possible on all jobs, resulting in scheduling advantages and cost savings to our customers. Our modular fabrication facilities allow us to accommodate all types and sizes of piping.

We configure the most efficient setup to match any type or size of pipe. All of Armistead Mechanical’s welding services meet the most demanding ASME codes and ANSI standards. We utilize welding processes from SMAW (shielded metal arc welding – STICK), GMAW (gas metal arc welding – MIG), GTAW (gas tungsten arc welding – TIG), GMAW pulse spray arc to GTAW automatic.

Armistead also uses ARC machines, incorporating state-of-the-art computerized orbital welding equipment to provide FDA-approved sanitary piping systems to pharmaceutical and consumer products companies.

Our UA fabrication facilities can produce and ship product to anywhere in the United States and Canada at a higher quality and more efficient pace. We can provide this service to other mechanical contractors.